Armalith®

New generation jeans

Armalith has hit the market of materials used to produce clothing for motorcyclists.

It is a reinforced type of denim that is more durable than Kevlar, Cordura and even leather.

Where is the secret of Armalith and what exactly is this material?

Reinforced denim

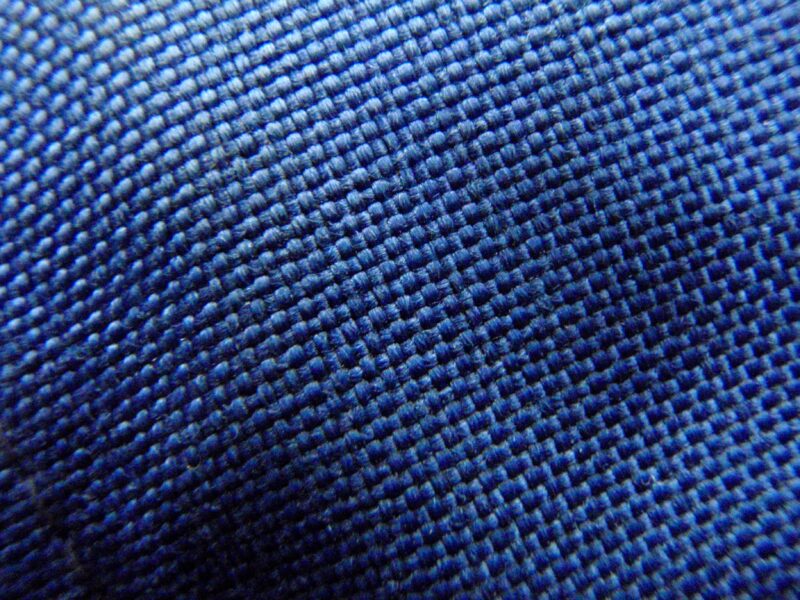

Armalith is a special type of jeans reinforced with UHMWPE (Ultra High Molecular Weight Polyethylene) fibers, which are resistant to abrasion and other damage, i.e. a special type of polyethylene fibers with high molecular density. These fibers are woven into the cotton yarn from which jeans are made and are an integral part of them.

It was invented in France in 2006 and is currently produced by the Spanish company Royotec. Armalith – like Cordura or Kevlar – was invented for the needs of the military and space technologies, but over time the benefits of using this material commercially were noticed. Companies producing clothing for motorcyclists especially like it.

Armalith has a number of advantages:

• It is lighter than typical Kevlar or Aramid reinforced denim.

• Thanks to the use of Lycra, it remains flexible, making it more comfortable to wear and ride.

• Unlike Kevlar-reinforced denim, it is single-layer, making it more airy and breathable.

• It is much more resistant to abrasion than denim, more durable than Kevlar or Cordura, and the latest version of Armalith 2.0 even outperforms cowhide in this respect.

Armalith composition:

Armalith is a mixture of synthetic and natural materials that are combined together at the yarn stage. It is treated as jeans because as much as 57% of the mixture is cotton – the same as in typical jeans. 33% of the composition are UHMWPE fibers, which strengthen the structure of the jeans and make it so durable, and the remaining 10% is the addition of Lycra, which gives the material elasticity. The version with Lycra, i.e. Armalith 2.0, was introduced in 2015. Armalith 1.0 without Lycra is still used in motorcycle clothing. It is equally durable, but lacks flexibility.

Thanks to its typical denim structure, Armalith is pleasant to the touch, looks great, is durable during long-term use and does not lose its properties over time. Both long-term exposure to UV rays and repeated washing (up to 1000 times) do not deteriorate the strength of UHMWPE fibers.

Depending on the use, for example urban or tourist clothes, we can also distinguish three classes of Armalith durability: basic A, stronger AA, and the strongest AAA.

Armalith vs. Kevlar and Cordura

Tests on the strength of UHMWPE fibers have proven that this material is up to 5 times more resistant to friction, 2.5 times more resistant to stretching than Kevlar, and at the same time up to 40% lighter and 10 times more resistant to sunlight. Thanks to such properties, in many areas UHMWPE fibers have replaced Kevlar, previously considered the most durable. An example is military equipment, where UHMWPE fibers have replaced Kevlar as a more effective, durable and lighter filling for bulletproof vests.

Cheaper to produce, but also characterized by excellent durability, Cordura is slightly worse than Kevlar, and therefore Armalith is better in this respect. However, Cordura has other advantages, such as high water resistance. The UHMWPE fibers themselves are completely hydrophobic, meaning they do not absorb water, but as a combination with cotton fibers it is not as waterproof as Cordura.

Armalith meets European safety standards

Armalith is one of the few single-layer materials that meet the conditions of the European motorcycle safety standard EN 13595-2, and certainly the only single-layer material that provides such wearing comfort, flexibility and breathability. That’s why so many manufacturers like SECA choose Armalith for their motorcycle clothing.

OTHER ARTICLES THAT